Forecast and Future Outlook for Industrial Nitrogen Generator Market

The Industrial Nitrogen Generator Market was valued at USD 4.69 billion in 2024 and is projected to grow at a CAGR of 5.8% from 2025 to 2034, reaching USD 8.23 billion by 2034. Rising demand for high-purity nitrogen in manufacturing, petrochemicals, food & beverage, electronics, and pharmaceuticals is driving market expansion globally.

Market Overview

Industrial nitrogen generators (INGs) produce nitrogen gas on-site from atmospheric air, offering a cost-effective and reliable alternative to conventional nitrogen supply methods like cylinders or liquid nitrogen. They are widely used across industries to prevent oxidation, ensure inert environments, and support manufacturing processes that require high-purity nitrogen.

The increasing adoption of automation, rising environmental regulations, and the need for continuous nitrogen supply are major growth drivers. ING systems offer benefits such as reduced logistics cost, consistent supply, and improved safety, which further boost their adoption in various sectors.

Market Drivers

- Rising Industrial Demand:

Industries like petrochemical, electronics, food & beverage, and pharmaceuticals require nitrogen for processes like blanketing, purging, packaging, and controlled atmospheres. - Cost-Effectiveness:

On-site nitrogen generation reduces dependency on cylinder or liquid nitrogen suppliers, lowering operational costs and transportation risks. - Regulatory Compliance:

Stringent environmental and safety regulations drive industries toward in-house nitrogen generation to ensure continuous and safe supply. - Technological Advancements:

Innovations in pressure swing adsorption (PSA), membrane separation, and cryogenic nitrogen generation systems increase purity levels and energy efficiency.

Market Challenges

High initial capital investment for ING systems and maintenance requirements may limit adoption among small- and medium-sized enterprises. Additionally, integrating these systems into existing industrial infrastructure can be complex. Companies are addressing these challenges by offering modular, scalable, and user-friendly nitrogen generators.

Market Segmentation

By Technology:

- Pressure Swing Adsorption (PSA)

- Membrane Nitrogen Generators

- Cryogenic Nitrogen Generators

By Flow Rate:

- Low Flow (up to 1,000 Nm³/h)

- Medium Flow (1,000–5,000 Nm³/h)

- High Flow (>5,000 Nm³/h)

By End-Use Industry:

- Chemicals & Petrochemicals

- Food & Beverage

- Pharmaceuticals

- Electronics & Semiconductors

- Metal Fabrication & Welding

- Others

Insights:

PSA-based generators dominate due to cost-effectiveness and high purity levels. Chemical, petrochemical, and food & beverage industries account for the majority of demand due to their large-scale nitrogen usage.

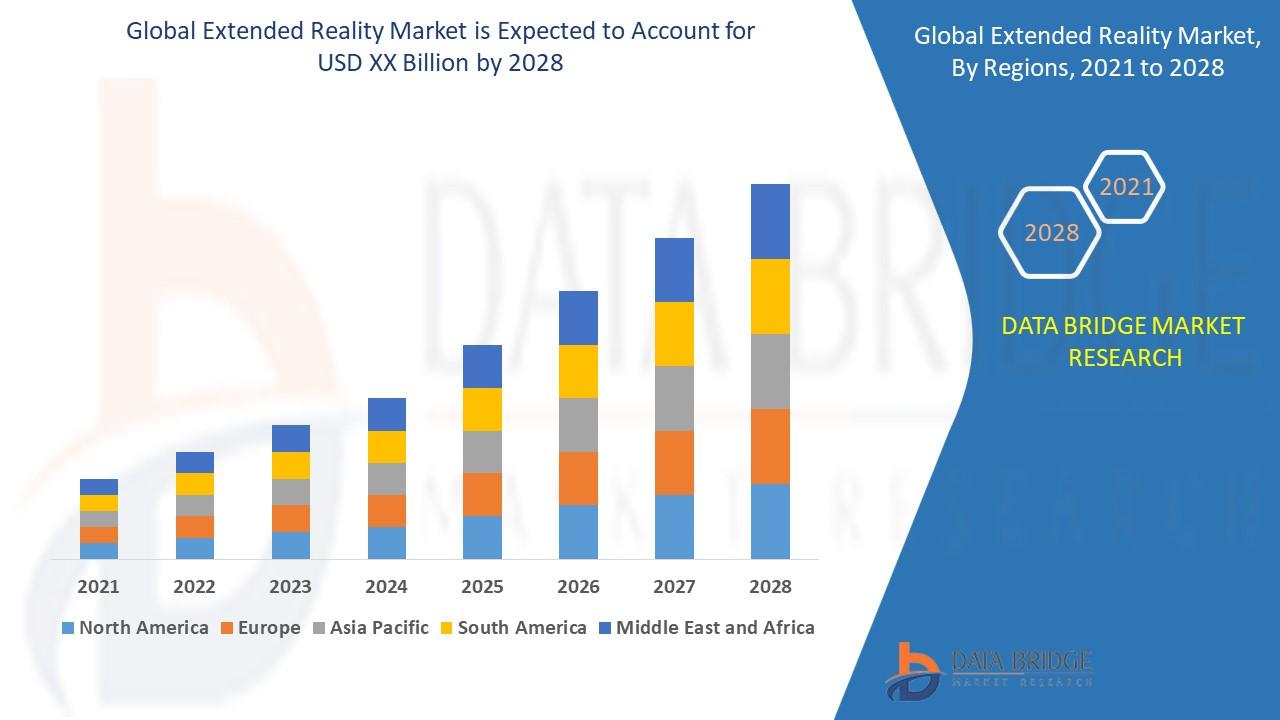

Regional Analysis

Key Regions:

- North America: Strong industrial base, advanced manufacturing, and high adoption of automation.

- Europe: Regulatory compliance, growing food & beverage and pharmaceutical sectors, and technology-driven adoption.

- Asia-Pacific: Rapid industrialization, expanding electronics, pharmaceuticals, and chemical industries.

- Latin America & Middle East: Emerging industrial sectors with increasing adoption of nitrogen generators.

The market growth is driven by industrial expansion, rising manufacturing activities, and investments in automation and clean energy solutions.

Key Players

Major companies in the industrial nitrogen generator industry focus on product innovation, high purity output, and customized solutions:

- Atlas Copco AB

- Air Products and Chemicals, Inc.

- Parker Hannifin Corporation

- Ingersoll-Rand plc

- Generon IGS Inc.

- Linde plc

- Messer Group GmbH

- Praxair Technology, Inc.

- Fusheng Group

- SIAD Macchine Impianti

These companies provide a wide range of nitrogen generation technologies and services to meet diverse industrial requirements.

Recent Developments

- Atlas Copco AB introduced energy-efficient PSA nitrogen generators for manufacturing and food applications.

- Air Products launched membrane nitrogen systems with high reliability for electronics and pharmaceutical sectors.

- Parker Hannifin Corporation enhanced modular nitrogen generation solutions for small and medium-sized industries.

- Linde plc implemented cryogenic nitrogen systems for large-scale industrial applications.

These advancements emphasize energy efficiency, reliability, and scalability in industrial nitrogen supply.

Future Outlook

The industrial nitrogen generator market is expected to grow steadily due to increasing industrialization, demand for high-purity nitrogen, and cost-effective in-house nitrogen production. Emerging trends include energy-efficient PSA systems, membrane-based nitrogen generation, modular scalable solutions, and integration with automated industrial processes.

LSI Keywords Used

- High-purity nitrogen generation

- On-site nitrogen production

- PSA nitrogen systems

- Membrane nitrogen generators

Conclusion

The industrial nitrogen generator industry is crucial for ensuring uninterrupted nitrogen supply across manufacturing, chemicals, food & beverage, pharmaceuticals, and electronics sectors. Adoption of energy-efficient, high-purity, and automated generators improves operational efficiency and compliance.

For detailed insights about industrial nitrogen generator, visit the official report page.

More Trending Latest Reports By Polaris Market Research:

Remote Sensing Services Market

EV Charging Communication Unit Market: Back Office Handling Services for Effective Performance

RegTech Market Size Worth US$ 66.15 Billion Propelled by 21.3 % CAGR From 2024 to 2032 Report By PMR